HIGH

SPEED

HIGH

PRECISION

RELIABLE

PRECISION

ALL AROUND

ZUSE provides machine solutions include with universal swivel milling head combining with the highly dynamic linear axis,achieves highlyproductive 5-axis simultaneous machining. The swivel milling head ispowered by top-performing and frictionless torque engines. Strongangular acceleration results in extremely short down times. The integrated hydraulic clamping.

Facilitates rough machining of high rigidity materials. Axial-radial bearings without backlash ensure high rigidity and a long service life. The swivel range reaches from -10° up to +180°.The direct measuring system by a high-precision angular encoder is integrated for maximum precision.

EDGE FOR

THE FUTURE.

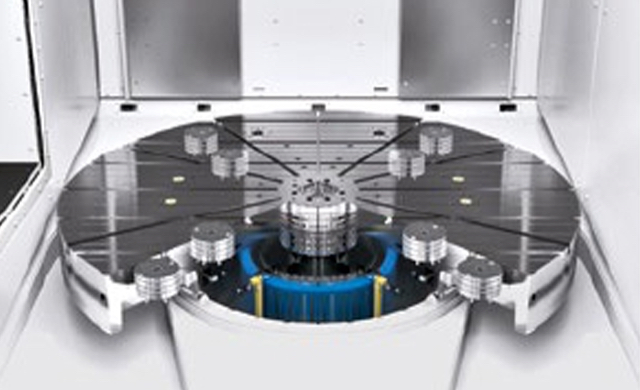

From the classic torque-engine-driven rotary tables to the latest technology mill-turn tables with customized revolution speed equipped with a high-precision absolute encoder, a direct reading system for high-precision milling and turning of difficult-to-machine materials is possible in a single clamping. Highest surface qualities can be achieved.

CONTROL

YOUR FUTURE.

The Heidenhain TNC 640 and Siemens Sinumerik 840D are your reliable process control well suited for 5-Axis Machining and Mill-Turing processes. The optimized Interface and the conversational programming (shop floor or DIN-ISO programming) ensure fastest programming. Their latest features, like the optionally available Adaptive Feed Control (AFC) and CollisionMonitoring (DCM) protect your machining operation. Direct import of dxf files is also possible. The TNC 640 / 840D feature short block processing times and enable accurate 3D simulation graphics. With its uniform digital design and its integrated digital drive control including inverters, it enables very high machining speeds and the best possible contour accuracy — particularly machining 3D contours.